|

|

|

|

|

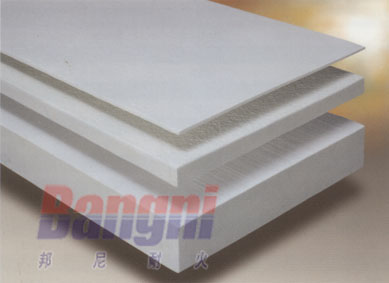

Features:

* Thickness, board smooth, flat

* Superior mechanical strength and structural strength

* Low thermal conductivity, good insulation properties, low shrinkage

* Erosion of the superior anti-air

* Cutting and easy installation

Application:

* A variety of high-temperature industrial furnaces for heat insulation surface or backing

|

|

* Ceramic kiln, mechanical, and metallurgical and other industrial furnace heat treatment furnace hot face lining materials

* Door, insulation materials such as kiln car

Third, classification temperature :1000-1800 ℃

Specifications:

· 1200 × 600 × 25/50MM

· 900 × 600 × 25/50MM

* Other special specifications can be customized

Physical and chemical indicators: |

| Project / Description |

BN-1000 |

BN-1260 |

BN-1400 |

BN-1600 |

BN-1700 |

BN-1800 |

| Category temperature (℃) |

1000 |

1260 |

1400 |

1600 |

1700 |

1800 |

| Color |

white |

white |

white |

white |

white |

white |

| Bulk density(Kg/m3) |

220-600 |

250-600 |

250-600 |

300-600 |

400-600 |

500-600 |

| Hotline Canada Change (%) 320 Kg/m3 |

800℃×6h<1 |

1000℃×6h<1 |

1200℃×6h<1 |

1500℃×6h<1 |

1500℃×6h<1 |

1600℃×6h<1 |

| Thermal conductivity (W/mK) 285kg/m3 |

| Average 400℃ |

0.08 |

0.08 |

0.08 |

0.08 |

|

|

| Average 800 ℃ |

0.13 |

0.13 |

0.13 |

0.13 |

|

|

| Average 1000 ℃ |

0.18 |

0.18 |

0.18 |

0.18 |

|

|

| Compressive strength(Mpa) |

0.5 |

0.5 |

0.5 |

>0.5 |

>0.5 |

>0.5 |

| Material |

Ceramic fiber |

Polycrystalline mullite fiber |

Alumina fiber |

| Chemical composition(%) |

| Al2O3 |

44 |

46-47 |

52-55 |

68 |

83 |

85 |

| SiO2 |

52 |

51-52 |

44-47 |

31.5 |

16 |

14 |

| ZrO2 |

- |

- |

- |

- |

|

|

|

| Note: Product technical data from the testing standards used were, on average, will fluctuate within a certain range, the data do not represent the product quality assurance data. |

|

|